Drilling Waste Management SystemOil drilling fluid solids control system is widely used in oil gas drilling and workover as drilling fluid purification treatment equipment.It can separate the solid and liquid in the drilling fluid, recycling the drilling fluid, also known as mud purification system.blob.pngThe whole drilling fluid recycling system tanks and pits can be separated and connected to match the rig drilling work request.The system have 5 phase purification equipment, including shale shaker, vacuum degasser, desander

HDD Mud TreatmentKD Slurry treatment plant. slurry separation system, desander plant, desanding plant for Trenchless HDD,Shield,Pipe-jacking TBM,Pile foundation engineering,Underground continuous wall milling slot machine.

Solids Control Equipment and System

Drilling Dluid Waste Management

Fracturing Fluid & Anti-drainage Treatment

Oilfield Sludge Sewage Treatment

Trenchless (HDD) Mud Recycling System

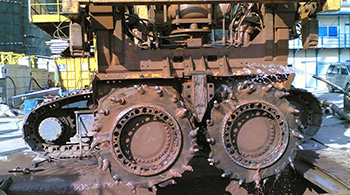

Shield&Pipe-jacking&TBM Slurry Separation System

Pile Foundation Engineering Slurry Treatment System

Underground Continuous Wall Desander Plant

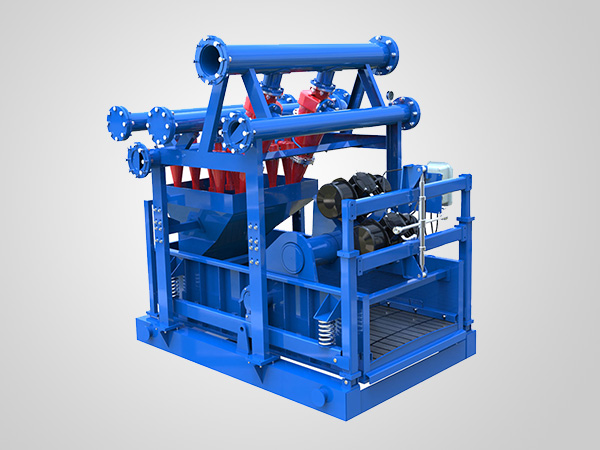

KD-500 Desanding Plant

KD-200 Slurry Separation System

Slurry Treatment Plant, Separation Plant

KD-100 Slurry Treatment System

LS606 Shale Shaker

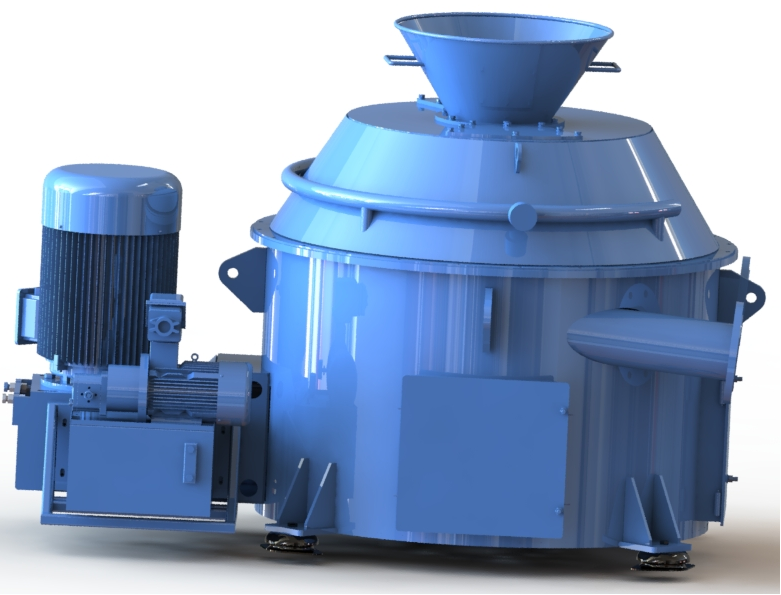

KQG30 Automatic Tank Cleaning

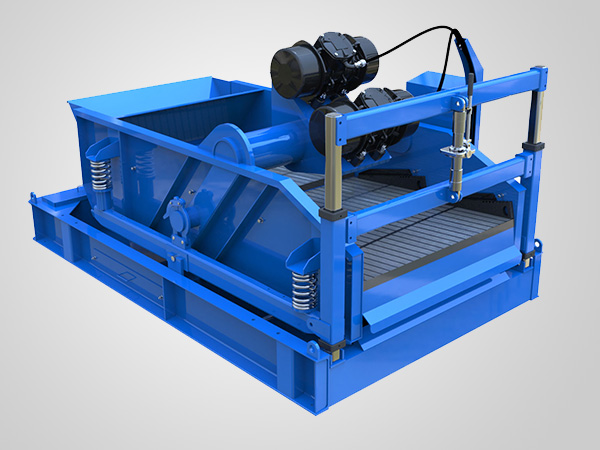

Linear Motion Shale Shaker

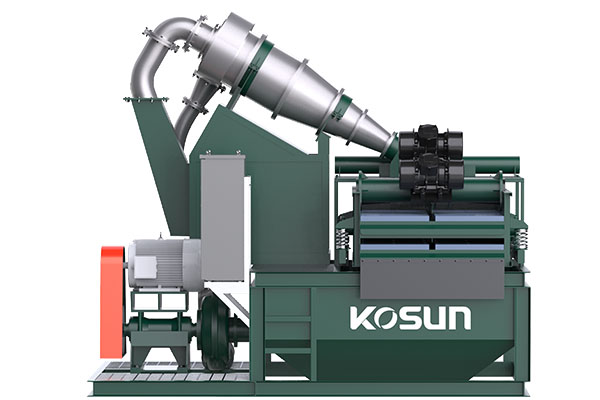

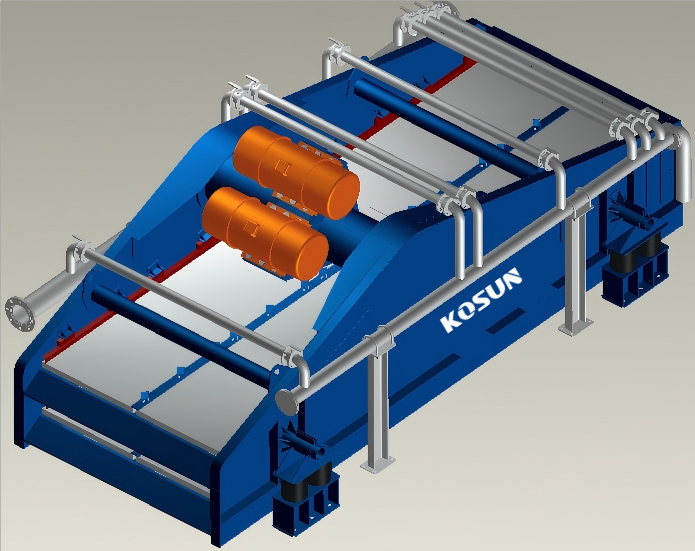

Hi G dryer

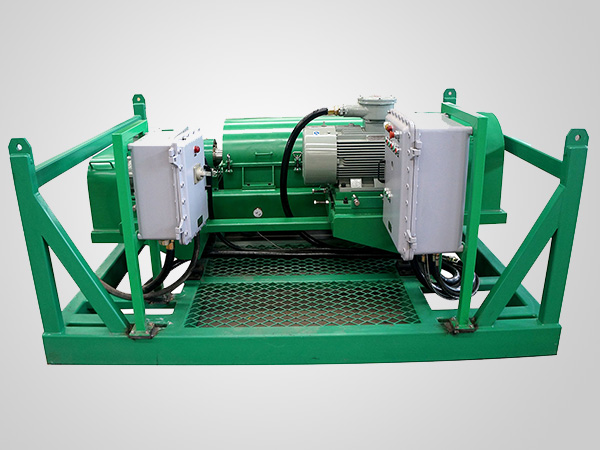

DC Series Decanter Centrifuge

Drilling Mud Cleaner

MD300 vertical desander

Vacuum Degasser

LS1850 Shale Shaker

Mud Gas Separator,Poorboy Degasser

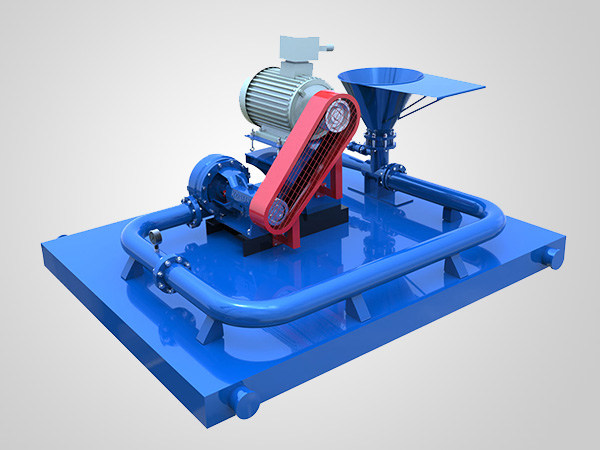

Jet Mud Mixer

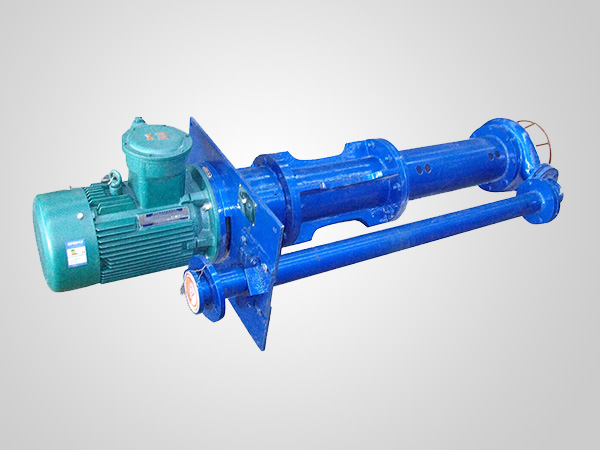

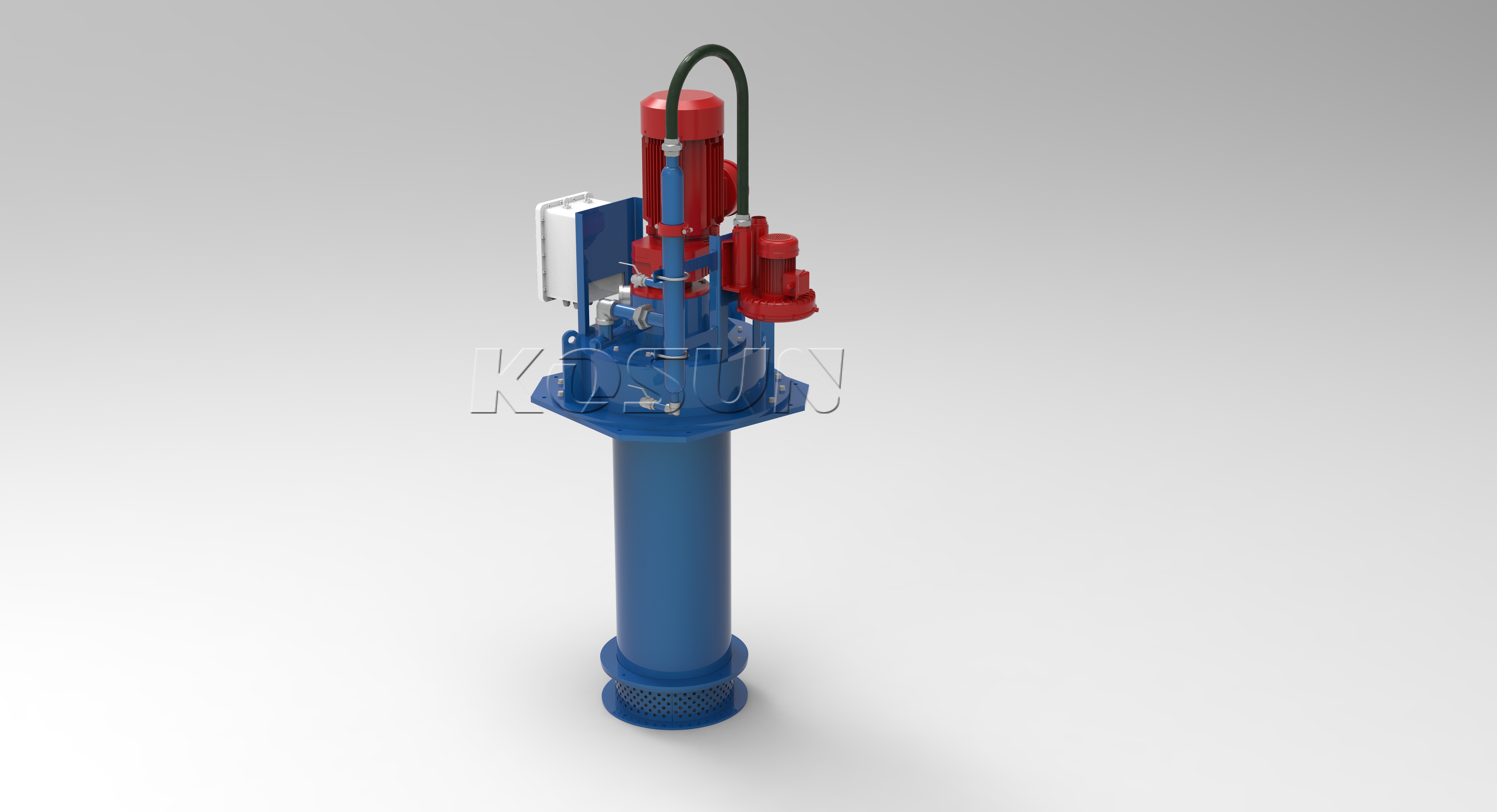

Submersible Slurry Pump

Balanced Elliptical Motion Shale Shaker

Mud Desilter

Mud Desander

Shear Pump

D Series Decanter Centrifuge

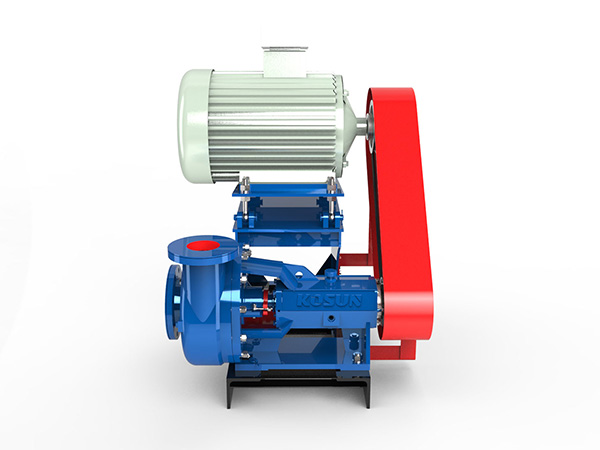

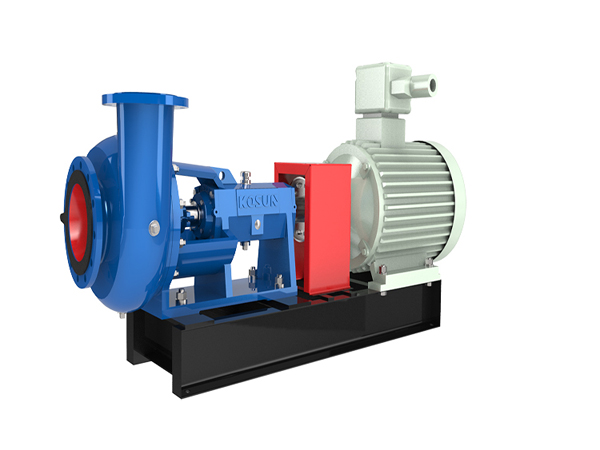

Centrifugal Pump

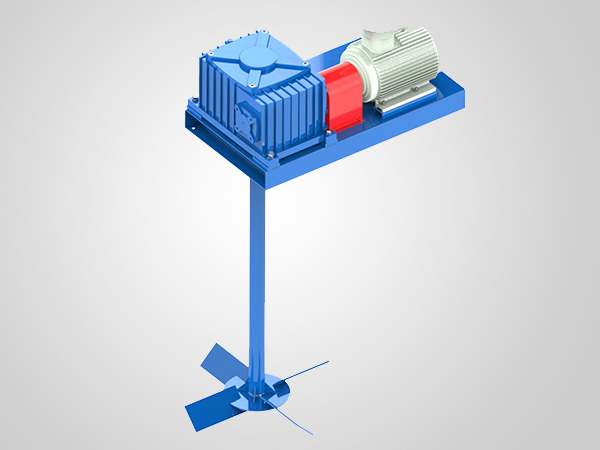

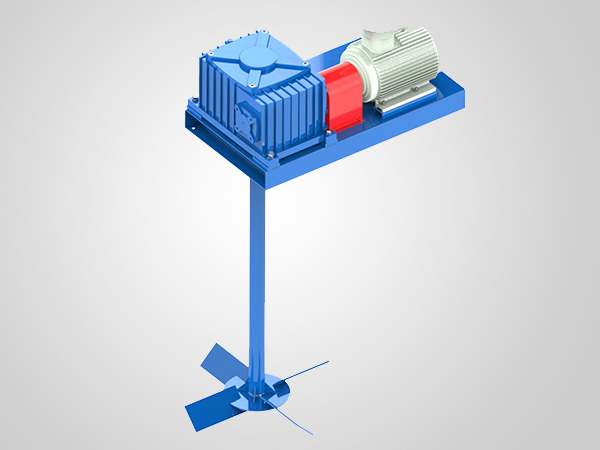

Mud Agitator

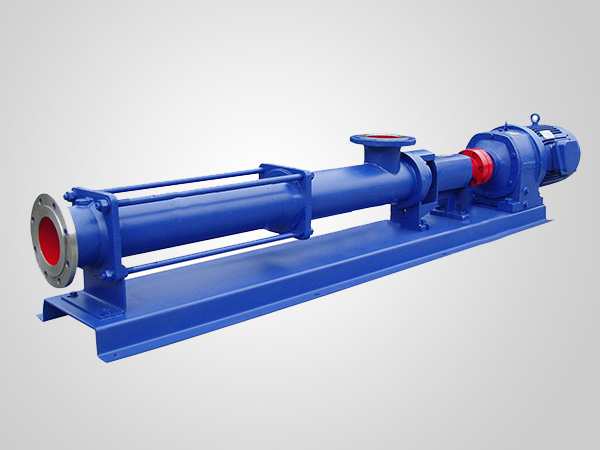

Screw Pump

Diesel tank

Drilling Mud Tank

Hydrocyclone

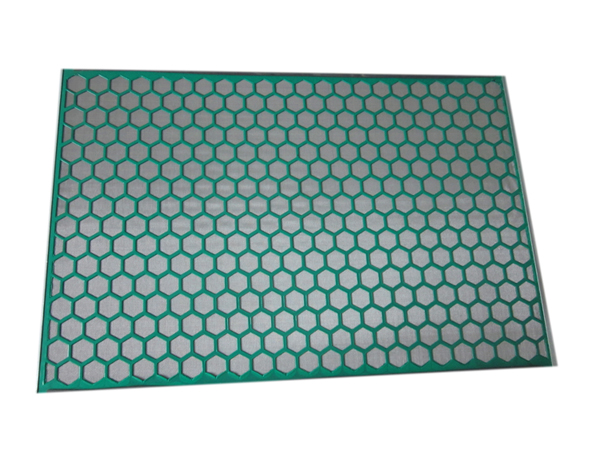

Shale Shaker Screen

Mud Gun

Water tank

The KFCQ300 vertical degasser

Vertical Cutting Dryer

DC Series Decanter Centrifuge

Oily sludge treatment (sludge sand treatment)

Oily sludge hot wash Processing system

D Series Decanter Centrifuge

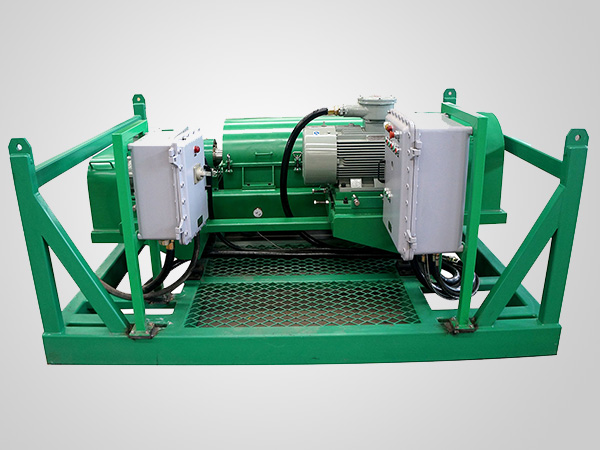

Mud Agitator

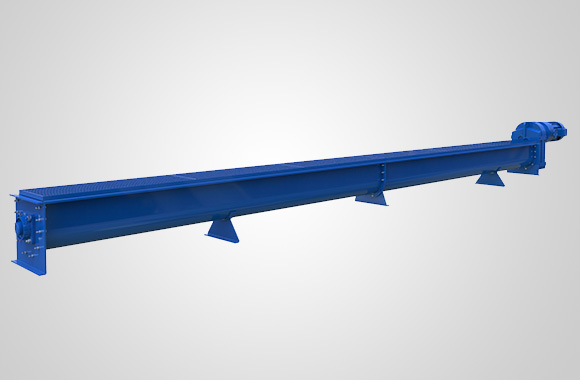

Screw Conveyor

Oil sludge treatment plant

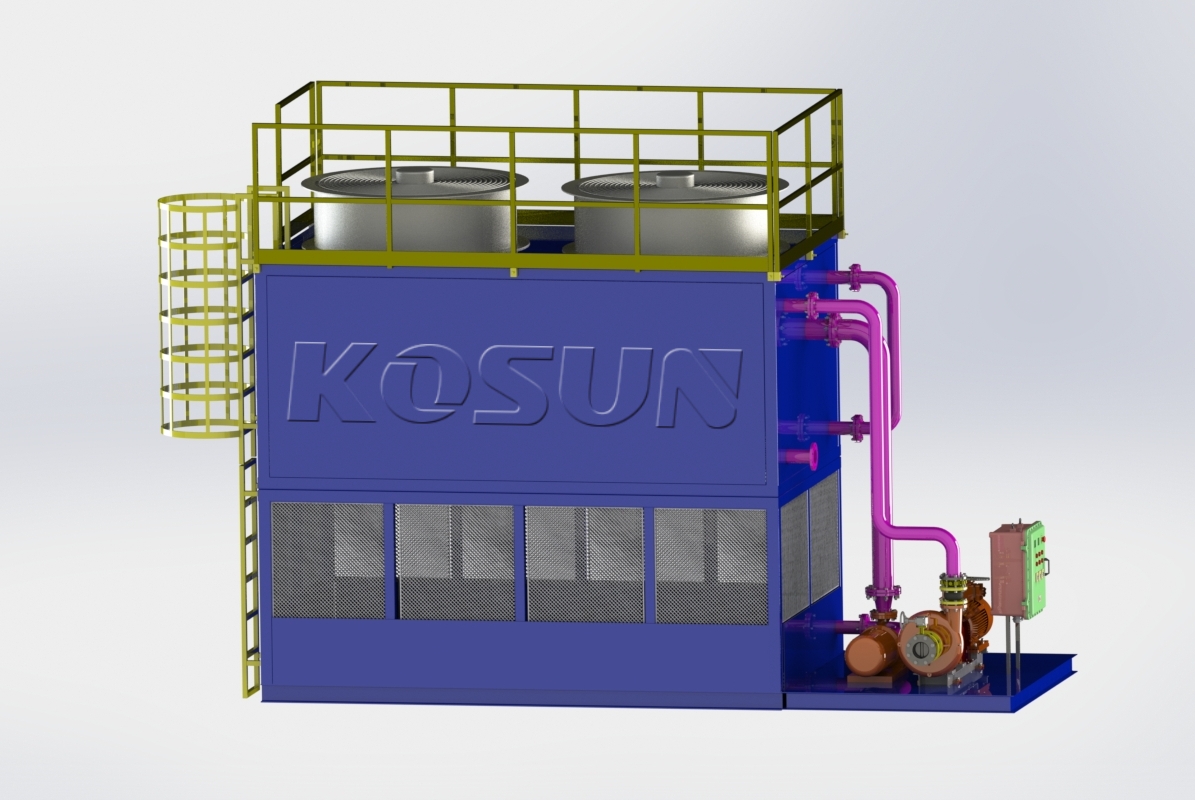

Mud (Drilling Fluid) Cooling System

Double track shaker

Mud Cooling System

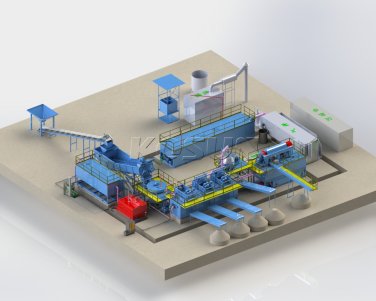

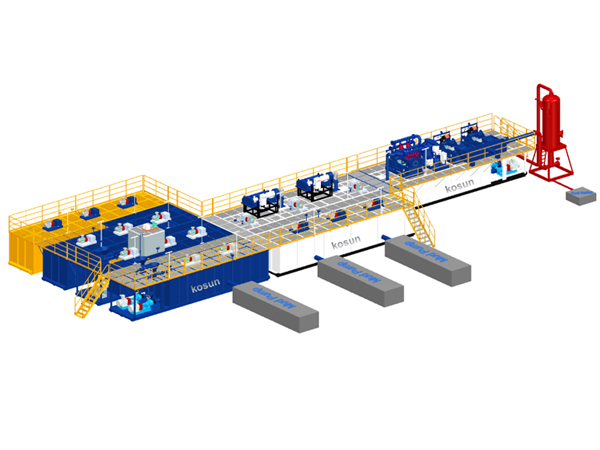

Drilling Mud Solids Control System

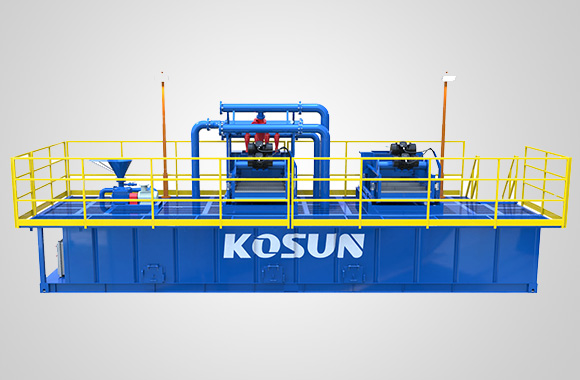

Mobile Solids Control System

Arctic Solids Control System

Skid-mounted Solids Control System

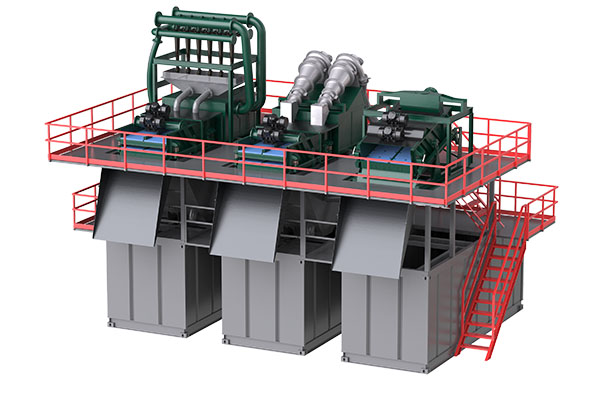

Maximize Drilling Efficiency with Advanced Shield Mud-Water Separation SystemsRevolutionize Your Tunneling and Drilling Operations with Cutting-Edge Separation Technology In modern tunneling, horizontal directional drilling (HDD), and slurry shield projects , managing drilling f...

Optimize Drilling Efficiency with Advanced Solid Control SystemsEnhance Performance and Reduce Costs with Cutting-Edge Solid Control Solutions In the oil and gas drilling industry, maintaining efficient operations while minimizing waste is crucial. A high-performan...

Linear Motion Shale Shaker: The Foundation of Efficient Solids Control SystemsRevolutionize Your Drilling Operations with Advanced Vibratory Separation Technology In modern drilling operations, effective solids removal is critical for maintaining drilling fluid integrity and pro...

Oil Sludge Treatment System: The Smart Solution for Sustainable Waste ManagementTransform Hazardous Oil Sludge into Valuable Resources In todays environmentally-conscious industrial landscape, proper oil sludge treatment is no longer optional - its a critical requirement. Our adva...

Drilling Waste Treatment System: Efficient Solutions for Sustainable Oilfield OperationsIn the oil and gas industry, proper drilling waste treatment is crucial for environmental compliance, cost reduction, and operational efficiency. A Drilling Waste Treatment System ensures safe disposal...

Mud Recovery System: Enhance Drilling Efficiency & Reduce WasteIn modern drilling operations, a Mud Recovery System plays a vital role in optimizing performance, reducing costs, and minimizing environmental impact. This system ensures efficient drilling fluid reco...

Kuwait 50 tons of landing sludge treatment project all shipped, Kosun's excellent performance has wonXi 'an Kesun undertakes Kuwait 50 tons of landing sludge treatment system has completed all product delivery, this is a set of high-tech integrated processing system, which is customized by Xi 'an Kesu...

The solid control system of Xi 'an KOSUN ZJ70 drilling rig was successfully deliveredXi 'an KOSUN (KOSUN) production of ZJ70 rig solid control system successfully sent to the domestic rig factory for supporting commissioning, this cooperation is Ukraine customer, the final use of t...

23Rd International Exhibition "Equipment And Technologies For Oil And Gas Industry"23Rd International Exhibition Equipment And Technologies For Oil And Gas Industry...

KOSUN participate in 2024 Oman Petroleum & Energy Show (OPES)KOSUN participate in 2024 Oman Petroleum Energy Show (OPES) Oman Petroleum Energy Showis the oldest and largest oil exhibition in Oman, radiating important markets in Western Asia, the Middle East, and...

Kazakhstan - Large oily sludge treatment projectAt the beginning of 2024, KOSUN Machinery successfully delivered an oily sludge treatment system to Kuwait. ...

Russia-ZJ30 Rig Solid Control SystemThe Russia-ZJ30 rig solid control system is capable of classifying and treating drilling mud. It can also perform mixing, degassing, weighting, and agitating of drilling mud, as well as supplying mud a...