Drilling Mud Solids Control System

Solids Control System is also called drilling fluid purification system, mainly used for solids control and solid-liquid separation to achieve drilling fluid recycling on the premise of guaranteeing stable drilling fluid performance. ...

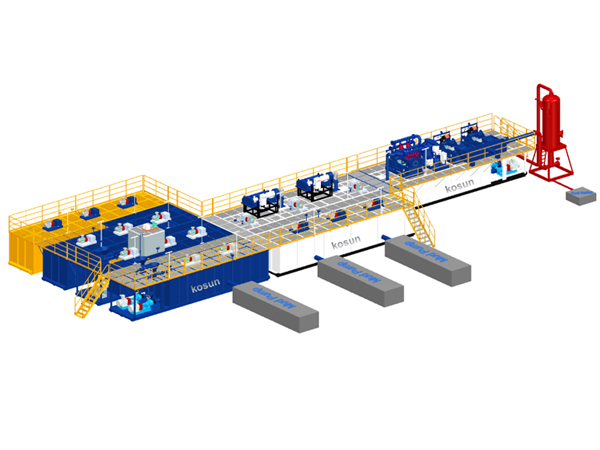

Solids Control System is also called drilling fluid purification system, mainly used for solids control and solid-liquid separation to achieve drilling fluid recycling on the premise of guaranteeing stable drilling fluid performance. The system is composed of 3-7 mud tanks with five-stage solids control, dosing and weighting equipment, which is applicable to drilling projects of 500-9000m and can meet the supporting requirements of 250-3000HP drilling rigs. KOSUN Environmental solids control system conventionally falls into skid-mounted and mobile types, and can be divided into cryophylactic (polar) and desert types according to different requirements on ambient temperatures, to meet different working conditions and customer requirements.>>Send an Enquiry sales@adkosun.com<<

Features of Solids Control System:

1. With modular design and small footprint, it can be flexibly configured and installed according to the customer’s requirements.

2. The side plates of mud tanks are designed with corrugated and load-supporting type, which are safer and can bear more load.

3. The system adopts a centralized electric control, being convenient for operation.

4. All equipment is designed with corrosion and wear resistance, with a long service life.

5. It is is adaptable to severe drilling operating conditions, being cold-resistant, heat-resistant, explosion-proof, leakage-proof, corrosion resistant and rainproof.

6. It is simple for installation and disassembly, and convenient for frequent moving along with drilling crew.

Operating Principle of Solids Control System:

Solids control system assembles five-stage solids control equipment, security equipment and other auxiliary equipment via manifolds according to their separation effects in an orderly way. Mud tank serves as a carrier and drilling fluid carrying cuttings directly enters shale shaker through a diverter. The shale shaker separates big cuttings particles from drilling fluid and the treated drilling fluid containing smaller particles passes through screens and enters the mud tank. If mud contains bubbles, self-priming device of vacuum degasser can suction the mud into the degasser for mud- gas separation. The degassed mud is then fed to desander and desilter via centrifugal pump. Solid- liquid separation of mud is continued in cyclones by using the principle of centrifugal sedimentation. Solid particles within 44~74 μm separated by desander and those within 15~44 μm separated by desilter are discharged and the mud enters the mud tank under centrifuge through manifolds connecting with cyclones for the last stage separation. Submersible slurry pump (screw pump) feeds mud to decanter centrifuge and solids particles over 2~15μm in diameter are separated by the centrifuge. Each mud tank is connected by using built-in pipes. During drilling operations, drilling fluids of different separation effects can be pumped for use as needed. Jet mud mixer on mud tank can prepare mud as needed.>>Send an Enquiry sales@adkosun.com<<

Tags: solids control, solids control equipment, solids control equipment for sale, solid control equipment drilling for sale, mud solids control, solids control system, solids control companies, solid control oil and gas, solid control in drilling, solid control equipment market, solids control services, solid control system drilling, solid control unit, drilling mud solids control, mud solids control equipment, drilling mud solids control system, solid control equipment drilling, rig solid control system, solid control equipment drilling offshore, solids control and waste management in drilling operations, solid control equipment used in drilling operation.