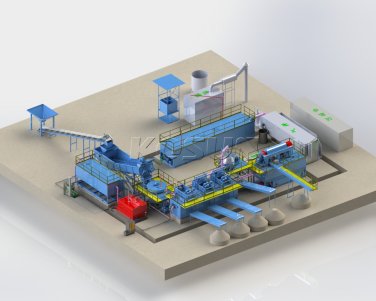

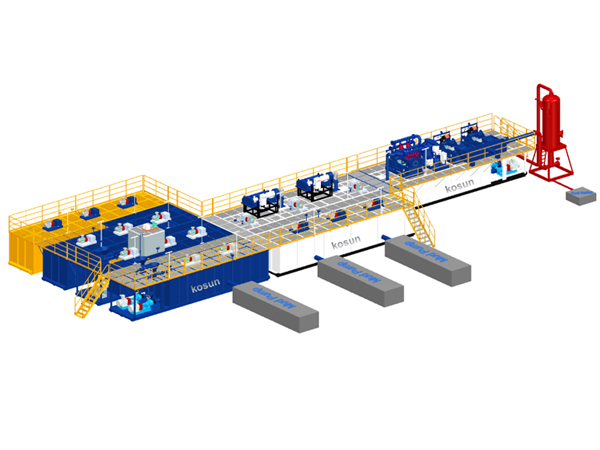

Drilling Waste Management SystemOil drilling fluid solids control system is widely used in oil gas drilling and workover as drilling fluid purification treatment equipment.It can separate the solid and liquid in the drilling fluid, recycling the drilling fluid, also known as mud purification system.blob.pngThe whole drilling fluid recycling system tanks and pits can be separated and connected to match the rig drilling work request.The system have 5 phase purification equipment, including shale shaker, vacuum degasser, desander

HDD Mud TreatmentKD Slurry treatment plant. slurry separation system, desander plant, desanding plant for Trenchless HDD,Shield,Pipe-jacking TBM,Pile foundation engineering,Underground continuous wall milling slot machine.

Solids Control Equipment and System

Drilling Dluid Waste Management

Fracturing Fluid & Anti-drainage Treatment

Oilfield Sludge Sewage Treatment

Trenchless (HDD) Mud Recycling System

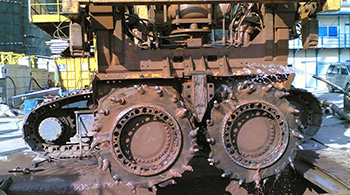

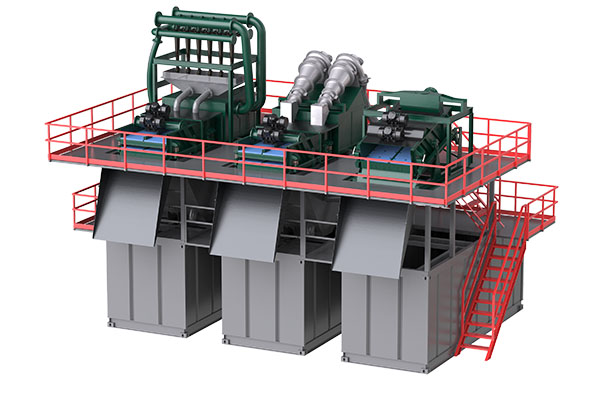

Shield&Pipe-jacking&TBM Slurry Separation System

Pile Foundation Engineering Slurry Treatment System

Underground Continuous Wall Desander Plant

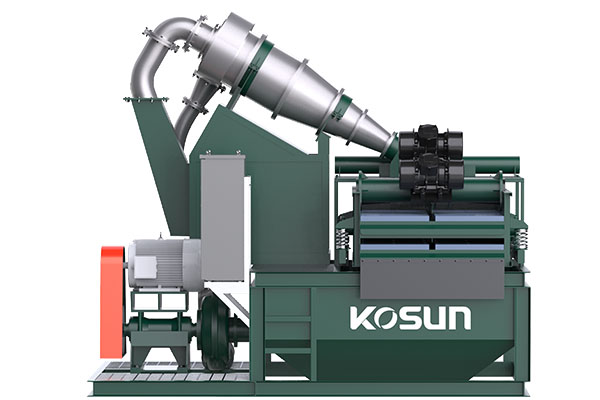

KD-500 Desanding Plant

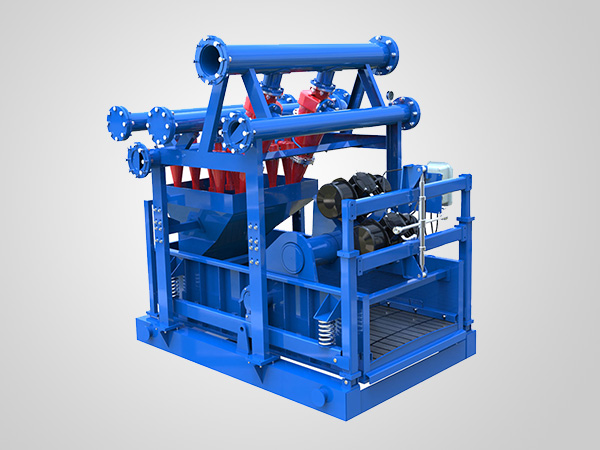

KD-200 Slurry Separation System

Slurry Treatment Plant, Separation Plant

KD-100 Slurry Treatment System

Mud Gas Separator,Poorboy Degasser

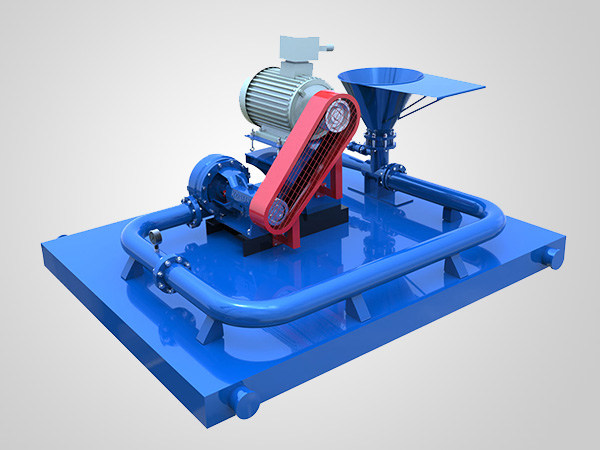

Jet Mud Mixer

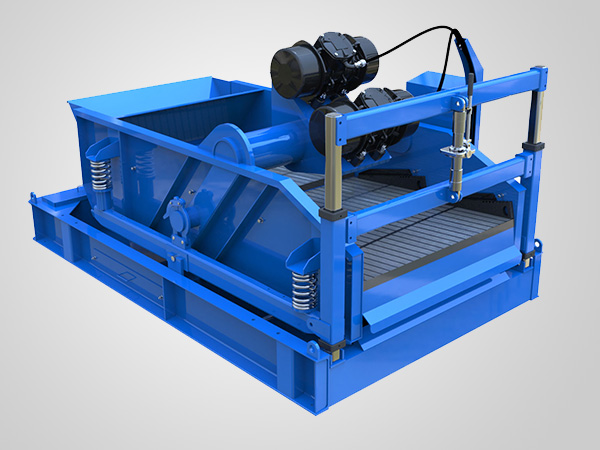

Linear Motion Shale Shaker

DC Series Decanter Centrifuge

MD300 vertical desander

Drilling Mud Cleaner

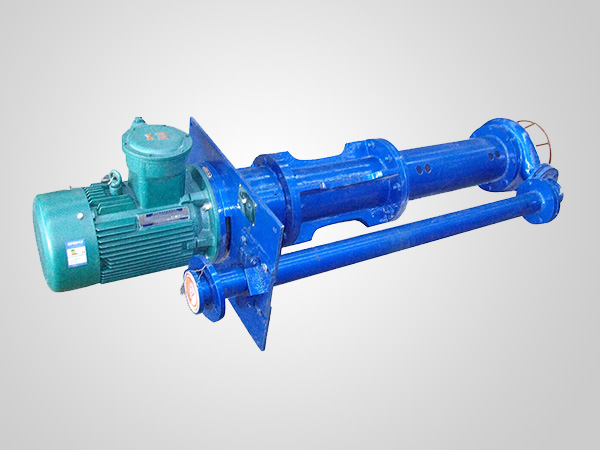

Submersible Slurry Pump

Balanced Elliptical Motion Shale Shaker

Mud Desilter

Mud Desander

Vacuum Degasser

Shear Pump

D Series Decanter Centrifuge

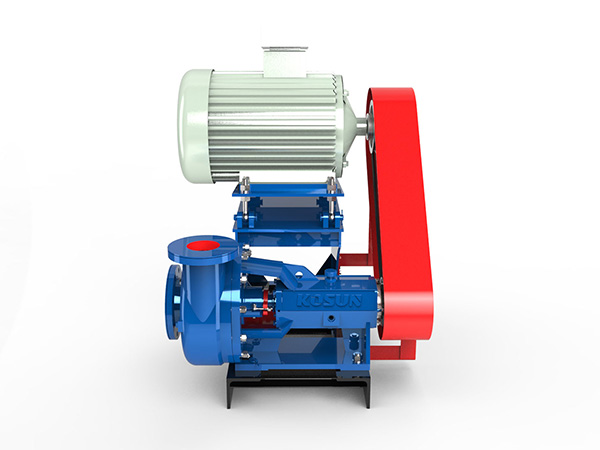

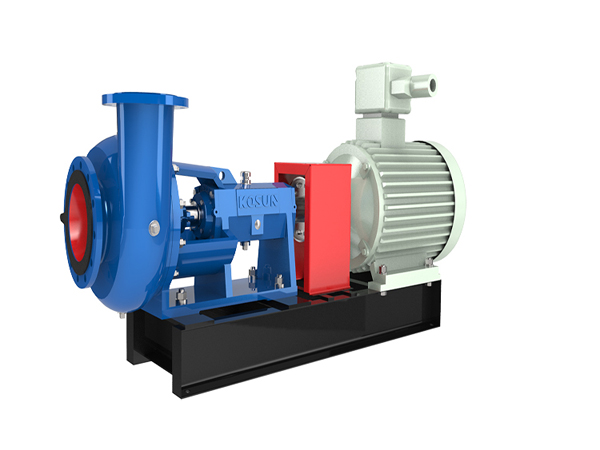

Centrifugal Pump

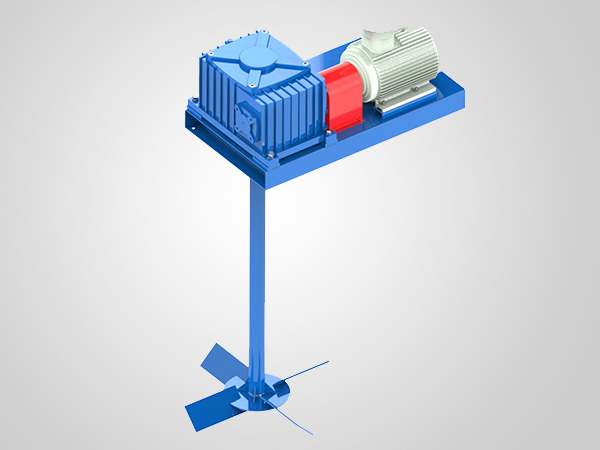

Mud Agitator

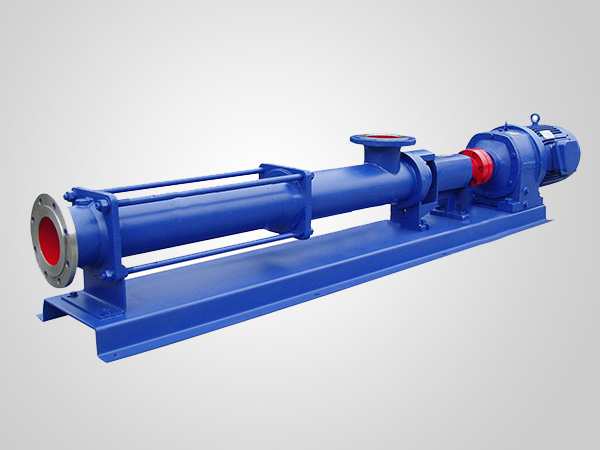

Screw Pump

Diesel tank

Drilling Mud Tank

Hydrocyclone

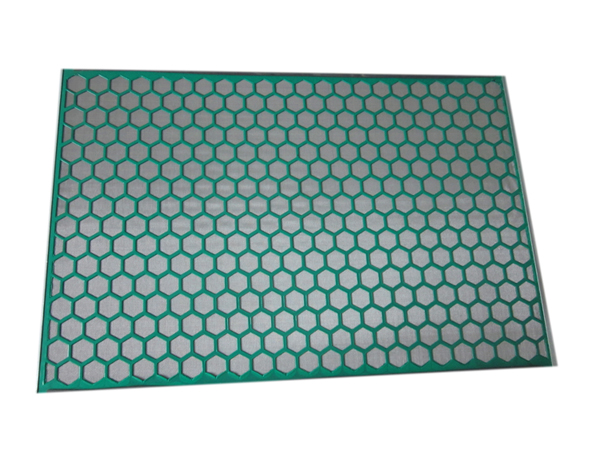

Shale Shaker Screen

Hi G dryer

Mud Gun

Water tank

Oily sludge treatment (sludge sand treatment)

Oily sludge hot wash Processing system

DC Series Decanter Centrifuge

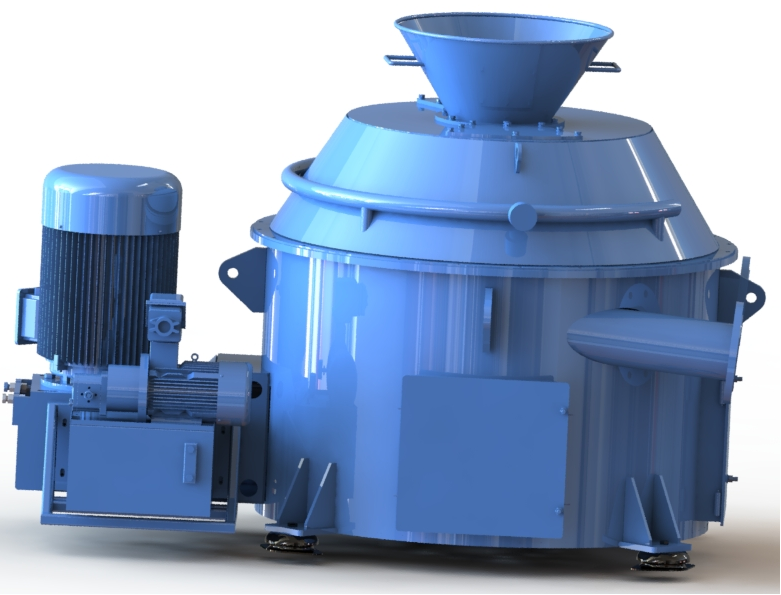

Vertical Cutting Dryer

D Series Decanter Centrifuge

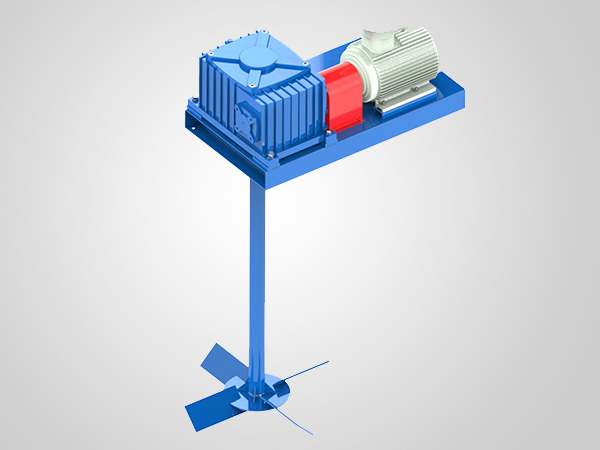

Mud Agitator

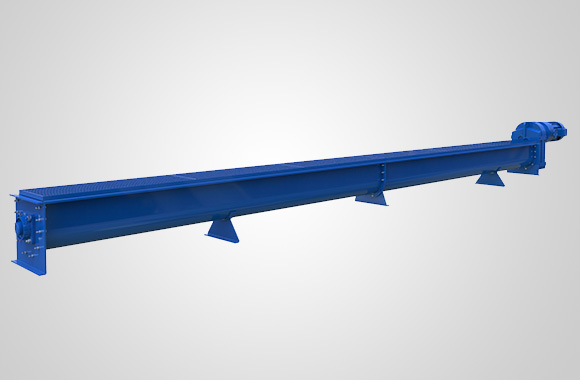

Screw Conveyor

Oil sludge treatment plant

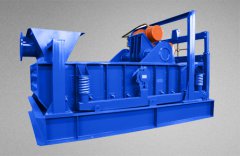

Double track shaker

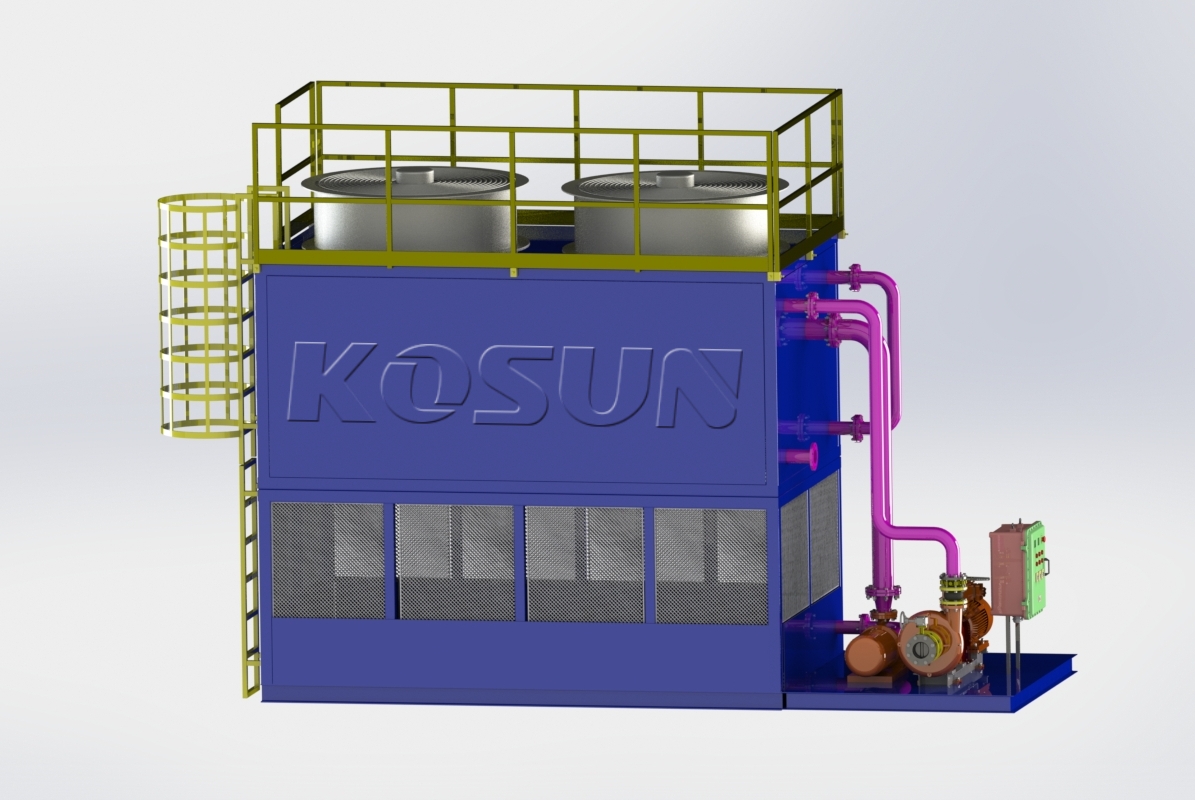

Mud (Drilling Fluid) Cooling System

Mud Cooling System

Drilling Mud Solids Control System

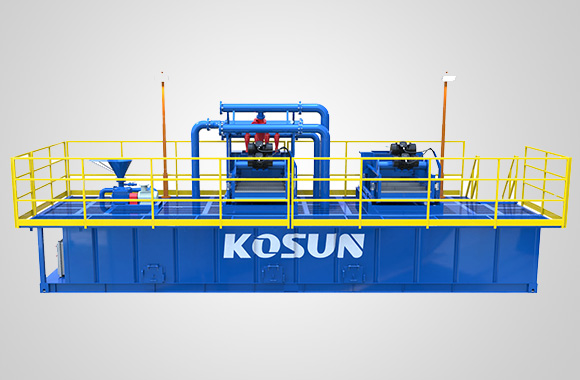

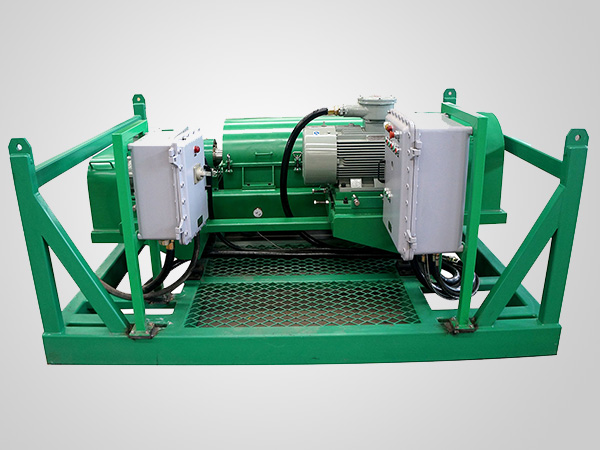

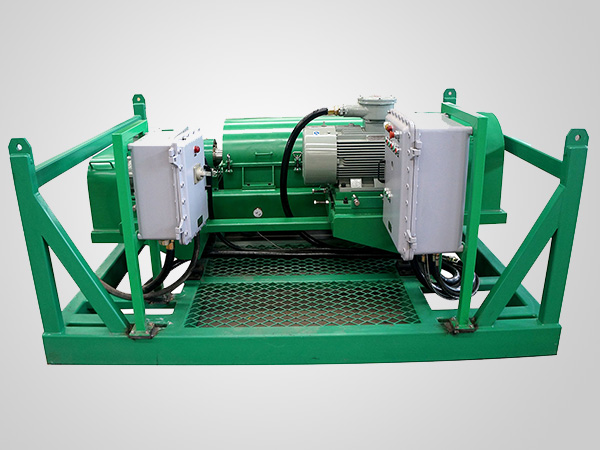

Mobile Solids Control System

Arctic Solids Control System

Skid-mounted Solids Control System

Screening machine of drilling fluid vibrating screenIn the process of drilling, when the drilling fluid returns to the wellhead with cuttings through the circulation system, flows into the shaker through the elevated trough, and then flows through the b...

Introduction to types of drilling mud and their treatment methodsIntroduction to types of drilling mud and their treatment methods: Drilling mud can be classified into two types: 1. Water-based drilling mud: Water-based drilling mud is the most commonly used type in...

Drilling fluid circulation process introductionThe drilling fluid circulates back from the wellhead, is sent to two (or three) vibrating screens through the overflow pipe, flows into the sand settling silo after screening, comes out of the sand set...

Oily sludge hot wash treatment systemOily sludge hot wash treatment system KOSUN Environmental Engineering Co.,Ltd closely follows the national policy, vigorously develops green environmental protection sludge treatment and soil remediati...

Why is it Necessary to Conduct Oily Sludge Treatment?The main reasons for conducting oily sludge treatment are environmental protection and resource recycling. Oil-containing sludge refers to solid waste that contains oil or petroleum products, typically...

What are the methods of cooling drilling fluid?Drilling fluid cooling is an important aspect of the drilling process as it helps maintain the temperature of the drilling fluid within the required range for optimal performance. There are several me...

23Rd International Exhibition "Equipment And Technologies For Oil And Gas Industry"23Rd International Exhibition Equipment And Technologies For Oil And Gas Industry...

KOSUN participate in 2024 Oman Petroleum & Energy Show (OPES)KOSUN participate in 2024 Oman Petroleum Energy Show (OPES) Oman Petroleum Energy Showis the oldest and largest oil exhibition in Oman, radiating important markets in Western Asia, the Middle East, and...

Kazakhstan - Large oily sludge treatment projectAt the beginning of 2024, KOSUN Machinery successfully delivered an oily sludge treatment system to Kuwait. ...

Russia-ZJ30 Rig Solid Control SystemThe Russia-ZJ30 rig solid control system is capable of classifying and treating drilling mud. It can also perform mixing, degassing, weighting, and agitating of drilling mud, as well as supplying mud a...

KOSUN 1000HP Drilling rig solids control system case in North AfricaThe 1000HP Drilling rig solids control system consists of 4 mud tanks, a shale shaker, a vacuumdegasser,Desander, desilter, four-stage purification equipment, to meet the processing requirements of dri...

Tail slurry treatment system working case in IndiaTail slurry treatment system working site in India...